AIRTEMP REFRIGERATION SERVICES

GST : 24AGXPP8466E1ZP

About Us

Established in 1991, Airtemp Refrigeration Services is a successful enterprise engaged as a manufacturer, exporter and wholesaler of Industrial Refrigeration & Air conditioning Plant, Roof Top Chiller Plant, Cold Room, Candy Plant, Fruit Feeder, Ageing Vat, Pizza Oven and other Hotel & Kitchen Equipments. The company has achieved grand success under the guidance of Dipak Patel who is highly experienced and full of energy. We have achieved continuous improvement in quality through streamlined teamwork, training and motivation. We believe that quality has to be built not just in the products like air conditioning plant and their designs but also into raw-materials, components and manufacturing processes.

Product Range

We are the manufacturer, exporter and wholesaler of the following product range:

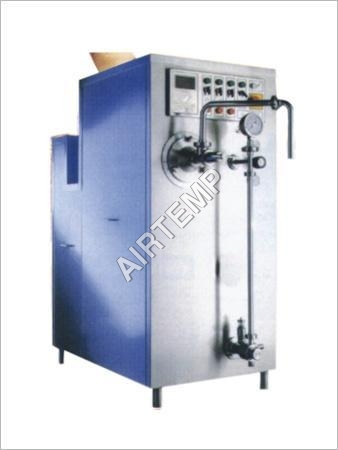

- Continuous Freezer

- Robust, sturdy design for continuous production

- Stainless steel frame and covering panels

- Hard chrome plated S.S. cylinder

- All product contact parts made of S.S. 304

- Completely automatic, hands free continuous production machine with consistent product quality

- Very easy to clean & assemble parts after cleaning

- Very easy & few setting points for various quality production with more safely control valve

- Low power consumption due to efficient refrigeration system & cylinder, beater design

- S.S. diaphragm pressure gauge

- Digital ice cream hardness controller

- Anti freeze protection device

- Speed variable device with indicator

- Suction and discharge pressure gauges for refrigeration circuit

- Hot gas supply to freezing cylinder

- Interlock and safety controls for single phase preventer, over load, l.p.-h.p. refrigerant pressures switch.

- Fruit Feeder

- Robust, sturdy design for continuous production

- Stainless steel frame and covering panels

- All product contact parts made of S.S. 304 and food grade plastic

- Very easy to clean & assemble parts after cleaning

- Very easy & few setting points for various quality production with more safely control valve

- S.S. hopper with mixer for storage of ingredient

- Three blades sealing rotary valve

- Variable speed controlled separate drive for rotor and ingredient feeders

- Blades made from special nickel alloy.

- Pasteurizer Vat

- Elegant look, robust and sturdy design

- Extra rich hygienic construction & easy to clean

- All product contact parts made of S.S. 304

- Water jacket construction for even heating

- Less fuel/power consumption due to proper insulation for external tank.

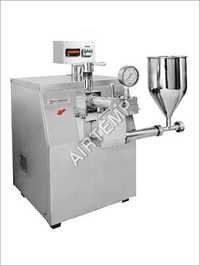

- Homogenizer

- Extremely compact mechanical design with superior finish

- To maintain a perfect hygienic condition, all parts are directly linked with ice cream mix made

- It is of either stainless steel or food grade material

- Specially designed pressure valve which gives high performance even during working hours

- Diaphragm type pressure gauge to maintain perfect hygienic condition

- Quick & easy to dismantle for perfect cleaning

- Particle size > 2 micron.

- Ageing Vat

- Extremely compact mechanical design

- Rectangular mix tank for proper mixing of ice cream mix

- All product contact parts made of S.S. 304 & castors for easy movements

- Glycol jacketed construction & effective stirrer gives even cooling and also maintains temperature on power failure (selected models)

- Less power consumption due to efficient refrigeration system and PUF insulation

- Bottom drive stirrer easily removable for complete cleaning.

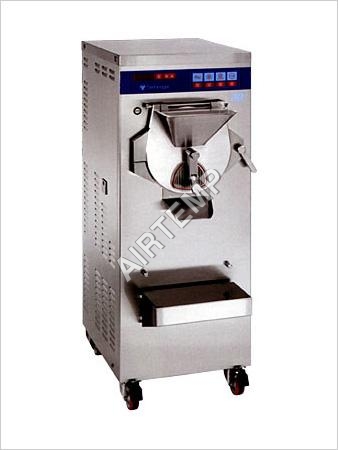

- Batch Freezer

- Robust, elegant aesthetically designed

- All product contact parts made of S.S 304 or food grade material

- Specially designed of beater & efficient refrigeration system

- Resulting in high product output with low power consumption

- Extremely compact mechanical design.

- Candy Plant

- Robust design for continuous production with outer & inner covers in S.S. 304

- Latest technology for continuous & positive heat transfer hence fast production

- Low power consumption due to efficient refrigeration system & PUF insulation

- Electronics temperature controller for consistent control

- Compact to superior finish with stainless steel construction.

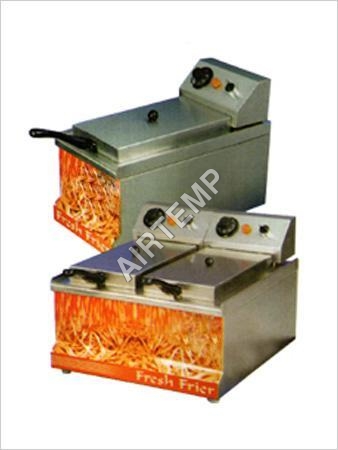

- Fresh Fryer

- Robust, elegant and aesthetically designed

- Designed for extra hygienic conditions made of S.S.-304

- Instant and even heating with temperature control

- All parts removable for easy cleaning and servicing.

- Pizza Oven

- Aesthetically designed

- Specially designed heating elements for even heating and long life

- Even heating with selectable heater eking (top, bottom or both) option can be used for multi products

- Toughened glass central window for visual baking inspection

- Baking chamber with internal bulb arrangement to visualize product kept for baking (Model PPO/S)

- High class thermal insulation to have minimum heat loss as well as energy saving

- Thermostatically temperature control in mini pizza oven & digital temperature control meter in pizza oven.

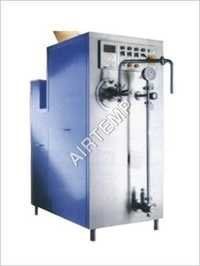

- Chilling Plant

- Robust, sturdy design for continuous production

- Stainless steel frame and covering panels/mailed steel

- Low power consummation due to efficient refrigeration system & chiller design

- Digital temperatures controller

- Anti freeze protection device

- Suction and discharge pressure gauges for refrigeration circuit

- Interlock and safety controls for single phase preventer, over load, and L.P.-H.P. refrigerant pressures switch.

- Hardening Tunnel

- Specially designed arrangement to hard candy & ice cream in very short time

- Robust, elegant and aesthetically designed

- Efficient refrigerated system & chambers, maintaining an even temperature even during operation

- Automatic control of temperature defrost system by specially designed programmable temperature controller

- High density PUF Insulation with outer & inner covers in S.S. 304.

- Roof Top Chiller Plant

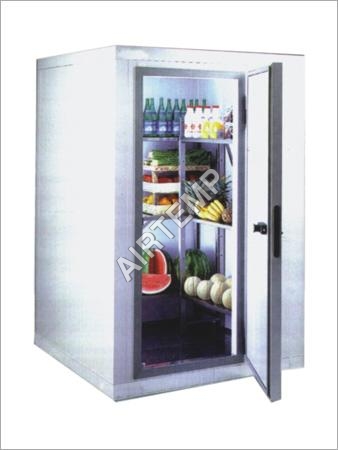

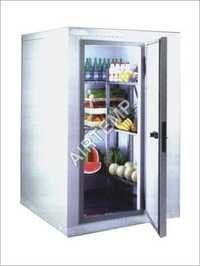

- Cold Room

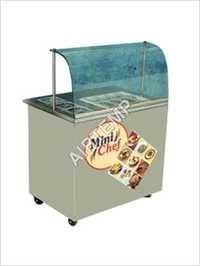

- Mini Chef

- Fast Food Parlour Equipment

- Chinese Kitchen Range

- Milk Pasteurizing Plant

- Ice Cream Mix Processing Machine

- Dairy Processing Machinery

Quality

Through R&D programmer, each machine is configured to standard specifications and the procedure is regulated. Our technocrats closely monitor the functioning of each equipment for its efficiency and durability. We guarantee our customers of quality products, proven design, excellent performance and best services. Our exclusive ranges of products have been appreciated all over the country for their unmatched quality and excellent designs. Each process of production undergoes stringent approval process. Quality has always been at the forefront of our pursuits. We are committed to provide quality air conditioning plant and other products through an effective quality management system in order to satisfy the specific requirements of our customers. The equipments are made up of best quality and are preferred for heavy duty, exclusive design, low maintenance, energy saving insulation and easy handling.

Product Features

The features of our products are as follows:

- Elegant look

- Robust & sturdy designs

- Extra rich in hygienic construction & easy to clean

- Less power consumption

- Extremely compact design

- Latest technology.

-

Ice Cream Making Machine -

Cold Room -

SS Mini Chef Counter -

Deep Fryer -

Chinese Gas Burner -

Commercial Pizza Oven -

SS Pasteurizer Plant -

Automatic Homogenizer Machine -

Industrial Ageing Vat -

Continuous Freezer -

Continuous Icecream Freezer -

Automatic Fruit Feeder -

Ice cream Candy Plant -

Industrial Hardening Tunnel -

Industrial Water Chilling Plant -

Water Chilling Machine Plant -

Roof Top Chiller Plant -

Automatic Pasteurizer Plant -

Batch Freezer -

Electric Bulk Milk Cooler -

Cooling Tower Water Treatment Descaling Chemical